Sidewall and Geometry Inspection

EVOLUTION 12 NEO

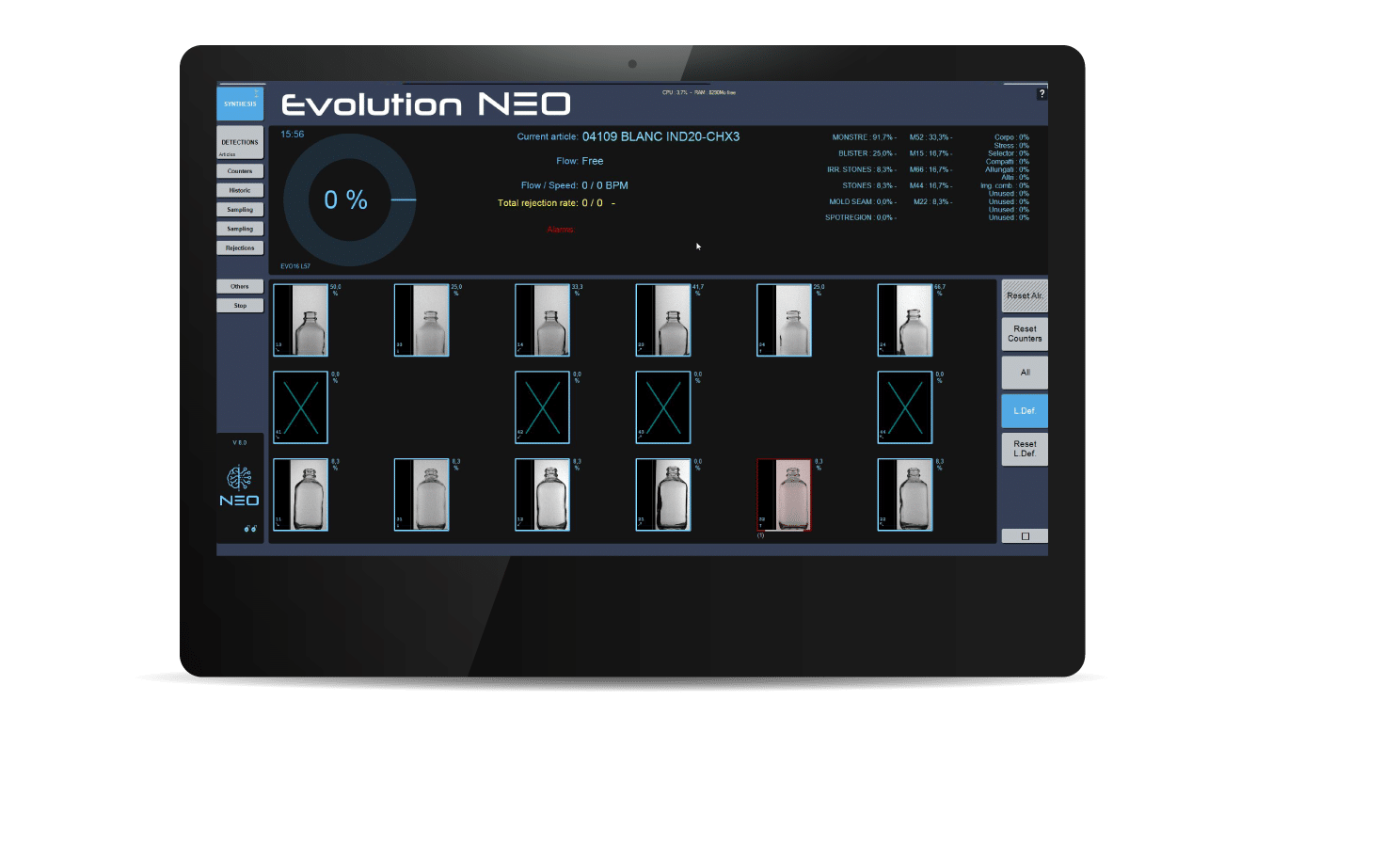

EVOLUTION 12 NEO is an intelligent sidewall inspection machine with 12 HD cameras. Thanks to its unique optical design, EVOLUTION 12 NEO provides full body coverage. Equipped with a 21.5’’ touchscreen, these machines offer a full display of 12 to 16 images. The latest generation cameras take sharper and more accurate images improving discrimination between different types of defects (eg small stones and blisters) A powerful processing unit with innovative design and reduced maintenance cost offers a platform for new inspection intelligence.

Accurate Inspection

INSPECTIONEVOLUTION 12 NEO offers five different geometry tools: Verticality, deformed container, deformed finish, body diameters, glass distribution in base

INSPECTIONBased on smart 3D modelling of the bottle, EVOLUTION 12 and 5 NEO are able to recognise the engraving and to inspect the engraved zone and the rest of the container.

NEO Intelligence inside

Inspection data created by the Evolution NEO is available not only on the machine itself but remotely for plant managers to monitor performance and initiate changes where necessary. In addition, defect images are available to hot end personnel, with the ability to share critical defect characteristics and defect images in real-time, alerting IS machine operators to instances of critical defect detection.

Data-driven inspection

A series of web-based trend analysis tools can be accessed to provide graphical views of defects in real-time, to assist glassmakers to understand the causes of defects, to simplify the adjustment of settings and to reduce false rejection rates.

Evolution 12 NEO inspects

Optional Features