Perfumes, cosmetics & tableware Inspection

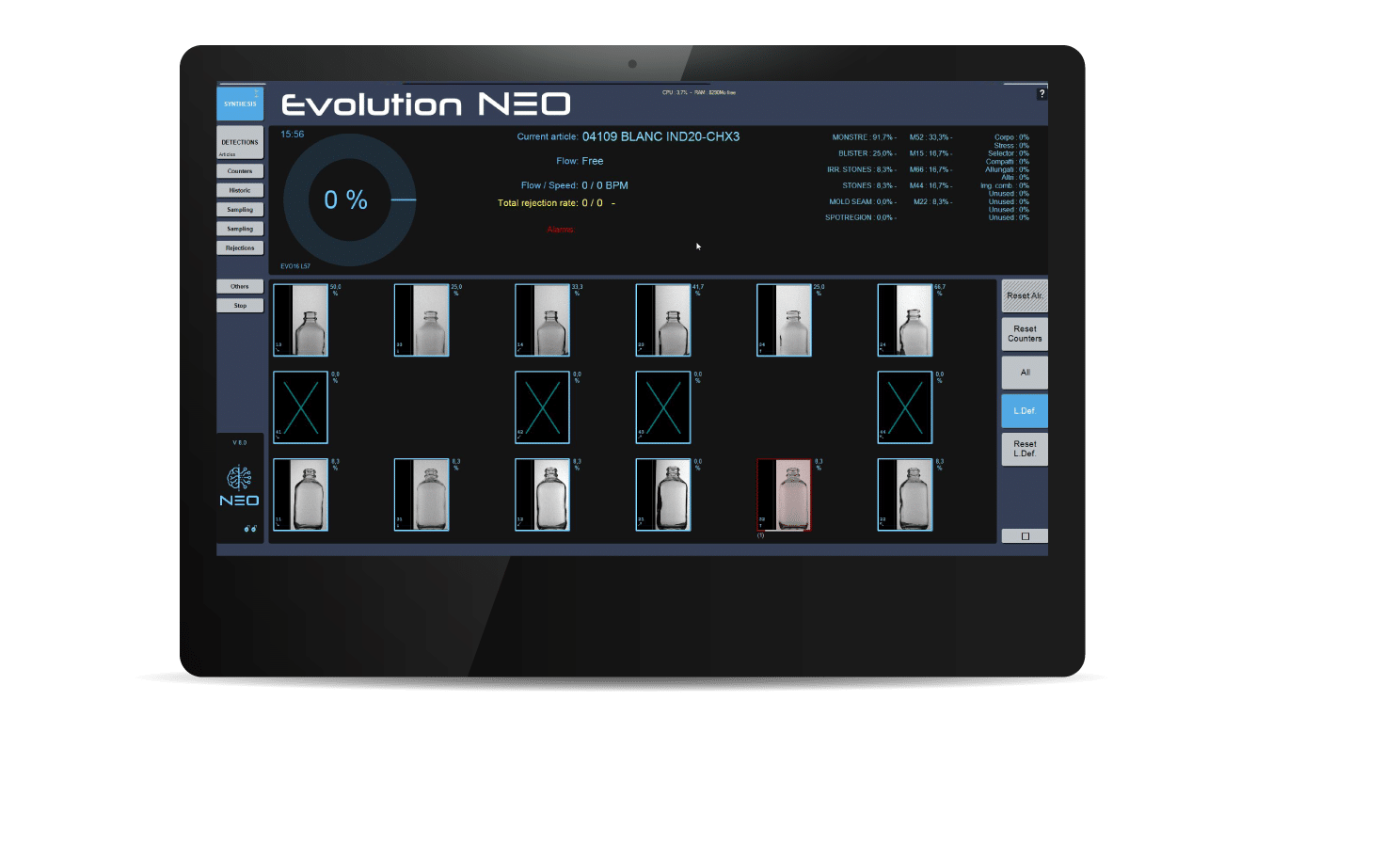

EVOLUTION ULTIMATE NEO

EVOLUTION Ultimate NEO is a sidewall inspection

machine with up to 18 HD cameras dedicated

for the cosmetic ware market, to inspect

cosmetic defects. Thanks to its unique optical

design, EVOLUTION Ultimate NEO provides full

body coverage. Equipped with a 21,5’’ touchscreen, EVOLUTION

Ultimate NEO machines offer a full display of HD

images. The new generation cameras take sharper and

more accurate images with better contrast on

transparent defects. A powerful processing unit with innovative

design and reduced maintenance cost offers a

platform for development of intelligent inspection

algorithms.

ONE MACHINE / TWO APPLICATIONS

Contrasted Defects

12 HD cameras

Direct optics – No mirrors

Stones, Inclusions, Blisters, Birdswings, Spikes, Stuck glass, Deformed containers, Lean, Diameters and height …

Cosmetics Defects

6 additional HD cameras

Dedicated to cosmetic and transparent defects

Cold moulds, Cat scratch, Surface blisters, Wash boards, Loading marks, Tears …

NEO Intelligence inside

Inspection data created by the Evolution NEO is available not only on the machine itself but remotely for plant managers to monitor performance and initiate changes where necessary. In addition, defect images are available to hot end personnel, with the ability to share critical defect characteristics and defect images in real-time, alerting IS machine operators to instances of critical defect detection.

Data-driven inspection

A series of web-based trend analysis tools can be accessed to provide graphical views of defects in real-time, to assist glassmakers to understand the causes of defects, to simplify the adjustment of settings and to reduce false rejection rates.